BUILDING & CONSTRUCTION

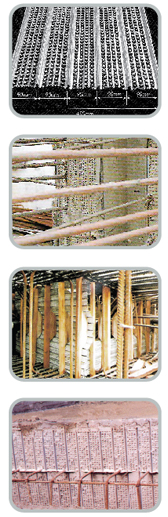

A | FORMRIB FOR CONSTRUCTION JOINTS

Cnventional joints require the removal of temporary timber joints and chiseling, hacking or other means to roughen the poured surface in preparation for subsequent pours. This could result in the weakening or cracking of joints, a lack of uniformity in bonding strength and even an inherently weak structure.

Formrib does away with all these disadvantages and problems. Made of galvanised steel mesh, formrib has integral V-shaped ribs to provide added rigidity and form a permanent shuttering for construction joints. It is manufactured from galvanised steel sheet.

PRODUCT BENEFITS

Formrib has many advantages over conventional timber formwork.

- Lightweight

Unlike heavy timber, formrib is extremely light and is easily transported to sites. - Permanent

Formrib forms a permanent shuttering for construction joints, unlike temporary timber formwork which must be removed after concrete is casted. - Convenient

Unique “fingers” in formrib retain the concrete that is poured, with the resulting surface, requiring no special bonding preparation for the next pour. - Greater Strength and Uniformity

Without the need to chisel, hack or roughen the poured concrete by mechanical means, there is less likelihood of inducing cracks which could weaken the bonding strength and joints. - Flexible

Formrib is easily bent and cut into required shapes, making it highly suitable for low-key or toggle joints. When used before rod reinforcement, rods can later be positioned by simply piercing through the mesh. - Time Saving

Formrib eliminates the stripping, cleaning, hacking and oiling normally associated with plywood formwork, as well as unnecessary drilling and carpentry works. - Reduce Presssure

Formrib’s open mesh design helps to reduce the water pressures build-up common with wet cement, so less support is needed.

Specifications

| Mesh Reference | Standard Sheet Size | Thickness* (mm) |

Weight kg/m2 ± 10% |

Material |

| OEMF2811 | 450 x 2200, 2500, 5000 | 0.3 | 2.35 | Galvanised Steel |

| OEMF2611 | 450 x 2200, 2500, 5000 | 0.4 | 3.14 | Galvanised Steel |

| OEMF2411 | 450 x 2200, 2500, 5000 | 0.5 | 3.92 | Galvanised Steel |